1000L Two Three Vessels Craft Beer Brewing Equipment for Beer Brewery

Shandong Tonsen equipment co., ltd. is an international comprehensive enterprise ,which is specializing in r&d,production,technical support and services for beer equipment and wine equipment .we provide complete beer brewing solutions that include: malt handling system, brew house system, beer fermenting/storage system,cooling system, cleaning system, control system, package line.

Craft Beer Complete System :

Brewery Brewhouse: 1000liter Used for Saccharification and Heating (Efficiency capacity 1000L/batch Total capacity around 1500L)

2 vessels Brehouse + Hot water tank

Mash & Lunter tank, boiling & whirlpool tank, hot liquor tank, etc.

3 vessels Brehouse + Hot water tank

Mash tun, Lunter tun, boiling & whirlpool tank, hot liquor tank, etc.

Inside lauter tun: water spary, spent grain dozer, agitate

Heating way: Electric heater heating

Electric heater inside, the agitate/stiring device is optional

Heating way: Steam jacket heating

Heating jacket on brewhouse tank body and bottom.

Fermentation tank: Could be 1000L or 2000L Used for beer fermenting

Fermenter Features

Our Fermentation tanks/tun available from 100L to 20000L (1 gallon to 20 gallon) and average 25% Head Space.

All tanks have a Dish top,

Cylinder body & 60/70° Cone Bottom.

Certified stainless steel(304,316) material for all tanks, with 100% TIG welded joints and seams with sanitary interior polish.

Dimple Plate jacket for Glycol cooling & high efficient Polyurethane foam insulated.

All tanks use Tri-clamp connections, are designed for up to 14.7 PSI and tested at 30 PSI.

We can customize fabricate any tank to meet your brewery's space and height restrictions.

Conical bottom, stainless steel 304/316, cooling jacket, triple clamp connecting, side OR top manhold,

Support customized OEM

1000L fermenting tank, total capacity 1350L

2000L fermenting tank, total capacity 2600L

Fermenter inside: pickling and passivating

Chiller machine 5HP and Glycol water tank/Ice water tank 1500l: Used for cooling the wort come from brewhouse and cooling fermenters

Automatic PLC control system /adopts siments brand, stainless steel, temperature control and display

50l CIP cleaning tanks for complete brewery cleaning and washing

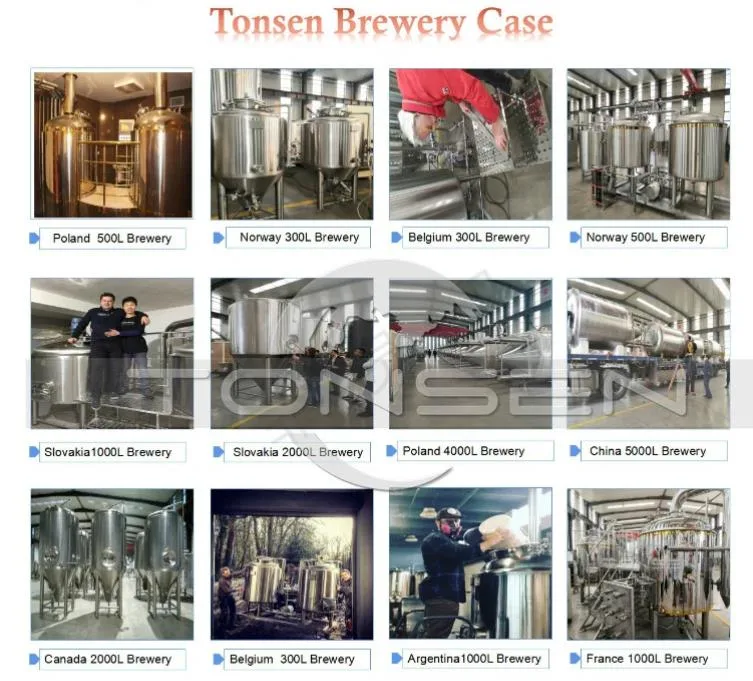

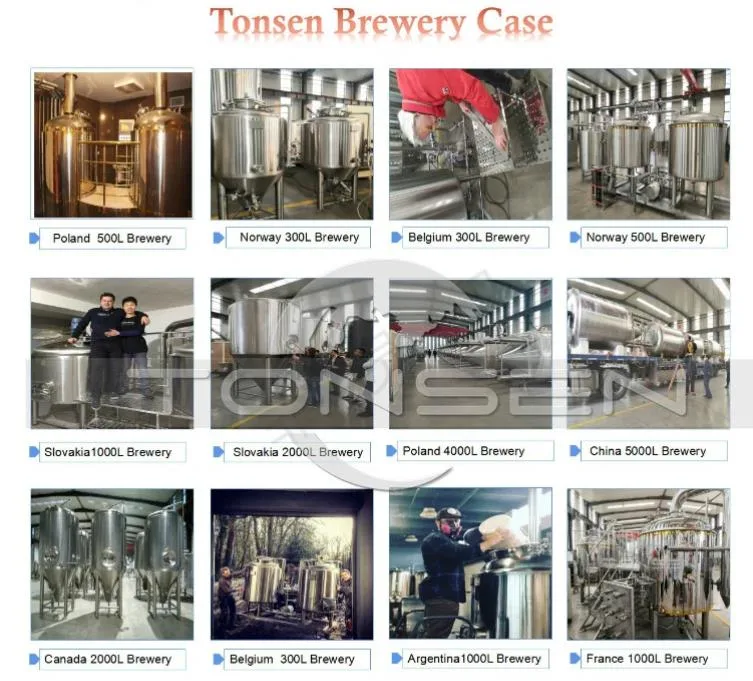

Reference Projects All Over the World

Shandong Tonsen Equipment Co.,Ltd Introduction:

We are professional craft beer brewing equipment manufacturer in China. With years experience, we have done many complete brewery system in France, UK, America, Germany, Holland and so on.

In Tonsen, Quality is our culture!

We'd like to share more information with you about us, about our factory, our products, our rawmaterial, manuracutring progress etc. The quality is not only shows by the tank appearance.

Generally there are four main elements may have influence for the equipment quality: The raw material, the drawing of the quipments, the welding and polishing and the testing.

(1) About the raw material:

About the sanitary stainless steel 304 , we use 3mm interior shell and 2mm exterior shell.And we usually take the samples to test it from the government. We ensure its quality!

(2) About the drawing:

Generally our technician will design the suitable layout accordingly before production once our customers confirmed their orders.

Then our workshop will do the manufacturing strictly according to the detailed drawing. It is normative for every order.

(3) About the welding and polishing:

We make sure the 100% TIG welding with pure argon gas shield. We use the central system of argon, instead of ordinary gas cylinder.

The argon will help to reduce the oxygenation. After welding, they will be polished to arrive to 0.2~0.4 μm without dead corner firstly, then do acid pickling and passivation.

Which will help to remove the oxygenation on welding line; and form protection film on the steel to avoid rust. It will help you to extend the tanks life time.

Here are our advantages:

1.We are one of the biggest pharmaceutical, beverage and brewery equipment manufacturers in China with more than 10 years experience.

2.Strong productivity of kinds vessels, we can produce satisfied product according your design.

3.Advanced technology assures strong welds and smooth seams.

4.Attention to detail at every step.

5.OEM / ODM services ,we provide one-stop services from one concept to a real product , and we can offer you very competitive prices

Our Service:

1.Our market team can serve you in 24 hours, so please feel free to contact at your convinent.

2.Our dedicated engineers can supply 2D,3D drawing for you if you needed.

3.If you need to inspect our factory, we can book the hotel and make the invitation letter for you.

4.Our market team with our engineer with more than 10 years experiences together can satisfy you with any technology problem;

5.Customize machine can be offered(voltage,material,dimension,heating source and so on)

After-service:

1.When shippment, we will supply a whole set of parts for backup.

2.If there is any parts damaged, we are surely can send the part to you in 24 hours.

3.Main machine is 3 years warranty, auxiliary machine is 12 months warranty,

4.electrical components is 18 months warranty, life long service.

Shandong Tonsen equipment co., ltd. is an international comprehensive enterprise ,which is specializing in r&d,production,technical support and services for beer equipment and wine equipment .we provide complete beer brewing solutions that include: malt handling system, brew house system, beer fermenting/storage system,cooling system, cleaning system, control system, package line.

Craft Beer Complete System :

| 1000L Per Batch Brewery System List | ||

| System | Components | Specification |

| Milling System | Miller | 500-800kg/h |

| Heating System | Boiler (steam heating) | 100kg/h |

| Brewhouse System (2 vessels or 3 vessels) | Mash / Lauter tun | 1000L/batch, total volume 1500L |

| Boiling / Whirlpool Tank | ||

| Heat-exchanger | Plate type 10M2 | |

| Hot water tank | Hot water tank and pump | 2000L |

| Fermentation System | Fermentation Tank | 1000L or 2000L based on request |

| Yeast Adding Tank | SUS304 Stainless Steel | |

| Refrigerator System | Refrigerator machine | 8HP |

| Pump / valve | 3T/H | |

| Ice water tank | 2000L | |

| CIP Cleaning System | Acid Tank | 100L per tank |

| Alkali Tank | ||

| Pump | ||

| Control System | PLC Control Cabinet | Semi-automatic |

| Accessories | Valves, pipes, connectors, pumps etc. | Matched |

Brewery Brewhouse: 1000liter Used for Saccharification and Heating (Efficiency capacity 1000L/batch Total capacity around 1500L)

2 vessels Brehouse + Hot water tank

Mash & Lunter tank, boiling & whirlpool tank, hot liquor tank, etc.

3 vessels Brehouse + Hot water tank

Mash tun, Lunter tun, boiling & whirlpool tank, hot liquor tank, etc.

Inside lauter tun: water spary, spent grain dozer, agitate

Heating way: Electric heater heating

Electric heater inside, the agitate/stiring device is optional

Heating way: Steam jacket heating

Heating jacket on brewhouse tank body and bottom.

Fermentation tank: Could be 1000L or 2000L Used for beer fermenting

Fermenter Features

Our Fermentation tanks/tun available from 100L to 20000L (1 gallon to 20 gallon) and average 25% Head Space.

All tanks have a Dish top,

Cylinder body & 60/70° Cone Bottom.

Certified stainless steel(304,316) material for all tanks, with 100% TIG welded joints and seams with sanitary interior polish.

Dimple Plate jacket for Glycol cooling & high efficient Polyurethane foam insulated.

All tanks use Tri-clamp connections, are designed for up to 14.7 PSI and tested at 30 PSI.

We can customize fabricate any tank to meet your brewery's space and height restrictions.

Conical bottom, stainless steel 304/316, cooling jacket, triple clamp connecting, side OR top manhold,

Support customized OEM

1000L fermenting tank, total capacity 1350L

2000L fermenting tank, total capacity 2600L

Fermenter inside: pickling and passivating

Chiller machine 5HP and Glycol water tank/Ice water tank 1500l: Used for cooling the wort come from brewhouse and cooling fermenters

Automatic PLC control system /adopts siments brand, stainless steel, temperature control and display

50l CIP cleaning tanks for complete brewery cleaning and washing

Material: stainless steel 304

Include: iye tank, hydrogen peroxide tank, hot water tank (optional)

Function: Used to clean all equipment after brewing

Reference Projects All Over the World

Shandong Tonsen Equipment Co.,Ltd Introduction:

We are professional craft beer brewing equipment manufacturer in China. With years experience, we have done many complete brewery system in France, UK, America, Germany, Holland and so on.

In Tonsen, Quality is our culture!

We'd like to share more information with you about us, about our factory, our products, our rawmaterial, manuracutring progress etc. The quality is not only shows by the tank appearance.

Generally there are four main elements may have influence for the equipment quality: The raw material, the drawing of the quipments, the welding and polishing and the testing.

(1) About the raw material:

About the sanitary stainless steel 304 , we use 3mm interior shell and 2mm exterior shell.And we usually take the samples to test it from the government. We ensure its quality!

(2) About the drawing:

Generally our technician will design the suitable layout accordingly before production once our customers confirmed their orders.

Then our workshop will do the manufacturing strictly according to the detailed drawing. It is normative for every order.

(3) About the welding and polishing:

We make sure the 100% TIG welding with pure argon gas shield. We use the central system of argon, instead of ordinary gas cylinder.

The argon will help to reduce the oxygenation. After welding, they will be polished to arrive to 0.2~0.4 μm without dead corner firstly, then do acid pickling and passivation.

Which will help to remove the oxygenation on welding line; and form protection film on the steel to avoid rust. It will help you to extend the tanks life time.

Here are our advantages:

1.We are one of the biggest pharmaceutical, beverage and brewery equipment manufacturers in China with more than 10 years experience.

2.Strong productivity of kinds vessels, we can produce satisfied product according your design.

3.Advanced technology assures strong welds and smooth seams.

4.Attention to detail at every step.

5.OEM / ODM services ,we provide one-stop services from one concept to a real product , and we can offer you very competitive prices

Our Service:

1.Our market team can serve you in 24 hours, so please feel free to contact at your convinent.

2.Our dedicated engineers can supply 2D,3D drawing for you if you needed.

3.If you need to inspect our factory, we can book the hotel and make the invitation letter for you.

4.Our market team with our engineer with more than 10 years experiences together can satisfy you with any technology problem;

5.Customize machine can be offered(voltage,material,dimension,heating source and so on)

After-service:

1.When shippment, we will supply a whole set of parts for backup.

2.If there is any parts damaged, we are surely can send the part to you in 24 hours.

3.Main machine is 3 years warranty, auxiliary machine is 12 months warranty,

4.electrical components is 18 months warranty, life long service.