Production description:

Based on the absorption of the foreign technology and innovate, there are more than 20 invention patents. All the parts are made of stainless steel 304(pipeline and inside and outside of tanks are polished very well). In the production process, we will make a very strict inspection on welding. The quality of our products reaches the first class in China.

Applications: Widely used in brewery,bar,hotel,home brewing.

We are professional manufacturer of produce 100L Micro Beer Brewing Fermentation Equipment. We are specialized in professional design,manufacture, installation and commissioning of various beer equipments and supporting facilities. With advanced technology, good quality and after-sale service, our products have been highly praised by our customers from many countries.

Detailed Images:

| Equipment Request | Components |

The Mash TunInner-Jacket(SUS316/304) thickness: 3.0mm External-Jacket(SUS316/304) thickness: 2.0mm Dimple jacket plate thickness: 3.0mm Heating way: steam heating Heat exchange area: 1 Insulation layer: Rock wool material, Insulation thickness: 80mm |  |

| The Blender of Mash TunThe speed of this blender can be controlled by PLC. Power: 0.75KW Output speed:1-43RPM( frequency control) |

The Lauter Tun & RakerInner-Jacket(SUS316/304) thickness: 3.0mm. External-Jacket(SUS316/304) thickness: 2.0mm Insulation layer: Rock wool material, Insulation thickness: 80mm Equipped with raker; Power: 0.75KW; Output speed:1-29RPM( frequency control) The raker can moved up and down as your needs automaticly or manually. The spent grain outlet also can be automatic or manulay. It's up to you!! |  |

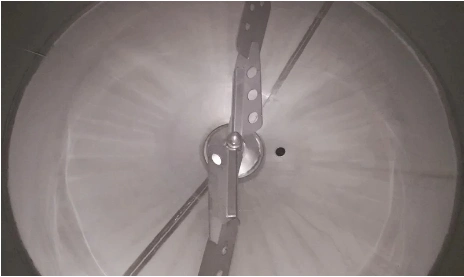

| The Milled Sieve The sieve is milled one in lauter tun. The filter plate gap is less than 0.7mm and the load of sieve is about 250kg/m2. It is made by machine. The gap is more well-distributed. Never leak spent grain. In addition, it's easy to take the milled sieve out of the lauter tun because it has three parts. |

| The Motor & Pump As you can see, we use ABB motors and VFD Food grade efficient centrifugal pump. The quality can be absolutely guaranteed. |  |

| The Steam Jacket & Colling Jacket Dimple jacket plates; the media is glycol water, alcohol water, steam. Insulation: Polyurethane-thickness: 80mm. |

Our Services:

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Our Company:

Jinan HIMAX Machinery Co., Ltd. specializes in designing, researching and manufacturing 100L Micro Beer Brewing Fermentation Equipment, beer bottling and canning line and the subsidiary equipment. Introducing European advanced technology and innovating on the technology, HIMAX company becomes the leader in domestic beer industry and the most professional supplier for liquid production and package turnkey project.

HIMAX company is located in Hi-tech Development Zone, Jinan, Shandong province, near Jinan international airport and Qingdao port, so it is convenient for land and sea transport. There are 80 employees, including 20 engineers and after sales engineers, the strongest after sales team in China, who are professional in mechanic, craft, and electric control.

With the purpose of customer's satisfaction and the management of "convergence of wisdom, quality assurance", HIMAX company offers more high quality products and excellent service, and helps the customer to establish more value.

Packing & Delivery:

| Outside Pachage | International Standard Wooden Package |

| Delivery Time | 30 working days after your payments received |

Customers visiting and references:

Welcome to visit our factory warmly!!!

If you have an interest in our beer machine, please kindly let me know and I would like to prepare you a best offer and help you to find a best solution for your project.

Contact with us:

James